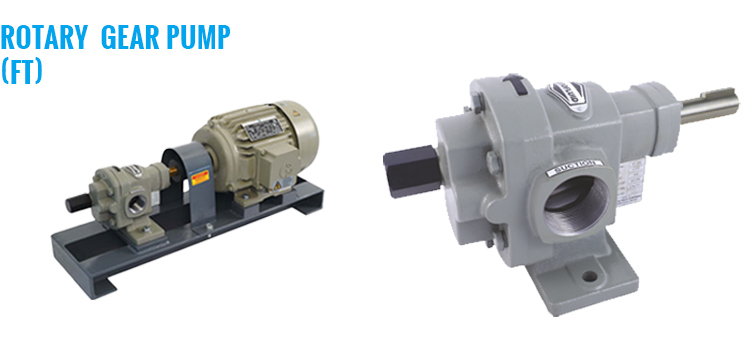

Rotary Gear Pump, Rotary Pump, Gear Pump Manufacturer from India

Rotofluid pumps is a Leading Manufacturer and Supplier of Rotary Gear Pump, Gear Pump, SS Gear Pumps, Rotary Pump and Jacketed bitumen gear pump in India. It is widely used in viscous and semi-liquids.

Fluid Tech Systems offer “ROTOFLUID” brand Rotary gear pump Model “FT” (Rotary Gear Pump) which is self-priming, foot mounting type positive displacement Rotary Gear Pump. Model “FT” having simple two pieces Cast Iron construction which is single helical modified profile carton steel gear shrink fitted on alloy steel hardened and grind finished shaft as gear firmly supported 4 nos. of self-lubricated sintered bronze bush bearing which ensure smooth running. Rotary Gear Pumps can be run in either direction with change in inlet-outlet port position. The relief valve operations can be reversed by simply changing the R.V. parts on opposite side.

The suction and delivery connections are available in 1/4" to 3" sizes. Rotary Gear Pumps can be operated up to pressure of 10 kg/cm² with 2.5 LPM to 500 LPM flow capacity. Rotary Gear Pumps are designed to run at 1440 RPM and viscosity up to 1,00,000 SSU and maximum temperature up to 200ºc. It is desirable to reduce speed for size above 1½" performance at low speed is always advantageous as it improves efficiency, reduce noise level and enhances operational life. The capacity will reduce in proportion to the speed.

Rotary Gear Pump Material of Construction

| Part | Material For Standard | Material For H.T. |

| Body | IS.210 FG 220 C.I. Grade | IS.210 FG 220 C.I. Grade |

| Back Cover | IS.210 FG 220 C.I. Grade | IS.210 FG 220 C.I. Grade |

| Gland Cover | IS.210 FG 220 C.I. Grade | IS.210 FG 220 C.I. Grade |

| R.H. & L.H. Gear | EN-8 | EN-24 [H. Nitrated] |

| Rotor/Stator Shaft | EN-19 | EN-19 |

| Bearing[Bushes] | Non Ferrous Sintered Bronze | Non Ferrous Sintered Bronze |

| Sealing | Neoprene oil Seal / Mechanical seal | “GFO” Pack Teflon / Mechanical Seal |

| R.V. Cap | Aluminum | Aluminum |

| Key for coupling | EN-8 | EN-8 |

Rotary Gear Pump Technical Specification

| Model | Suction & Delivery Size | Capacity at 1440 RPM | ||

|---|---|---|---|---|

| LPM | US GPM | M³/hr | ||

| FT - 025 | 1/4" x 1/4" | 2.5 | 0.6 | 0.1 |

| 05 | 1.3 | 0.3 | ||

| FT - 050 | 1/2" x 1/2" | 10 | 2.6 | 0.6 |

| 20 | 5.2 | 1.2 | ||

| FT - 075 | 3/4" x 3/4" | 25 | 6.6 | 1.5 |

| 30 | 7.9 | 1.8 | ||

| FT - 100 | 1" x 1" | 35 | 9.2 | 2.1 |

| 50 | 13.2 | 3.0 | ||

| FT - 125 | 1 ¼" x 1 ¼" | 75 | 19.8 | 4.5 |

| FT - 150 | 1 ½" x 1 ½" | 110 | 29.0 | 6.6 |

| FT - 200 | 2" x 2" | 225 | 59.4 | 13.5 |

| FT - 250 | 2 ½" x 2 ½" | 350 | 92.5 | 21.0 |

| FT - 300 | 3" x 3" | 500 | 132.0 | 30.0 |

Rotary Gear Pump Features

- Simple and Efficient design.

- Single helical gear design.

- Low noise.

- Wide capacity range.

- Easy to maintain.

- With relief valve design.

- High efficiency.

- Optionally available in double helical gear design.

- Self priming pump.

- Bi-direction positive displacement pumps.

Rotary Gear Pump Application

- Refineries.

- All kind of mineral Oils.

- Printing inks.

- Dyes and Resins.

- Glycerin and Glycol.

- Bitumen.

- Fuel oil, Diesel oil, Furnace oil.

- Power plant.

- Steel plant.

- Cement plant.

- Oil storage installation

×

×